The problem with most slippers is that they're cheaply made with the wrong materials. Even natural materials that are great in clothing - like cotton, simply aren't right for slippers. Why is that?

Frankly, your feet are special. They have more sweat glands than anywhere else on your body and they're the furthest from your heart, so they get cold easily. Your feet are your foundation and they deserve to be treated right.

Nootkas covers all the bases for you, here's how:

New Zealand Merino

Our slippers are made with Merino wool sourced exclusively from New Zealand, which enforces cruelty-free farming by law. To create the perfect climate controlled environment for your feet, we hand felt the wool, producing a dense textile filled with insulating air pockets. The cure for cold feet!

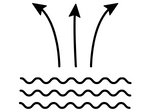

Breathable and Wicking

The unique molecular structure of wool makes it a moisture-wicking powerhouse. Efficiently moving dampness away from your feet to evaporate. Whether you're prone to foot sweat or simply looking for a better slipper, Nootkas will keep your feet dry and comfortable in all four seasons.

Naturally Odor Resistant

Wool possesses a truly remarkable property - it is naturally resistant to bacteria. The bacteria present in sweat is responsible for the unpleasant odors that linger in footwear and clothing. Amazingly, wool resolves this issue at its core by preventing the growth of this funk producing bacteria altogether!

Fair Trade & Handmade

All of Nootkas partners and production facilities are Fair Trade Certified. Our wool slippers are meticulously hand crafted in a solar powered workshop in Nepal. Each pair of slippers represents a three day labor of love - one day to wet felt and two days to cure and shape in the sun. This process also helps us ensure excellent quality control.

Zero Drop Construction

This design feature helps maintain the natural and neutral position of your foot in the slipper. In turn, promoting optimal foot and joint alignment while reducing the overall stress on your joints. Further, the wool footbed foundation will mold to your foot over time providing a gently customized support system for your feet and joints.

Made to Roam

Our slippers are low profile, flexible and incredibly lightweight, making them a breeze to pack and carry. They provide a convenient and cozy buffer between you and any unfamiliar floors - while making your feet feel right at home. Whether you're flying or driving, our minimalist designs ensure they won't take up too much space in your bag.

The Best Slippers for Cold Feet:

Closed heel house shoes are the warmest choice for cold feet. These styles are also spacious enough to comfortably wear socks. For super cold feet we recommend pairing our incredible alpaca wool socks with your favorite pair of wool house shoes.

The Best Slippers for Sweaty Feet:

Slippers with an open heel are the best choice for sweaty feet because they allow adequate airflow, while insulating and maintaining a consistent temperature inside the slipper.